Rebar Corrosion Scanning in Concrete

Rebar Corrosion Scanning in concrete can locate corrosion of rebar and post-tension cables within the concrete using state-of-the-art technology. Reinforcing steel locations are marked directly on the concrete surface to ensure safe and efficient drilling that will preserve the structure’s integrity and reduce the need for repairs or patching. This helps our clients conduct core drilling without accidents, injuries, or delays. A concrete GPR rebar Scan is also useful when preparing for a renovation that includes electrical outfitting, plumbing, fire protection services, drain installation, and ductwork.

Rebar Corrosion Scanning in Tampa, Orlando, Clearwater

Concrete corrosion Rebar Scan for EMBEDDED ELECTRICAL SERVICES

When rebar corrosion scanning in commercial and industrial locations is needed, accurate detection of electrical conduits is essential for preventing safety risks, power outages, and costly damages. Concrete GPR Scan for PT Cables Daytona provides two specific but different scanning services in this area: Elevated concrete slab scanning and concrete slab-on-grade locating. Elevated concrete slab scanning involves detecting embedded electrical conduits before core drilling a hole through the slab.

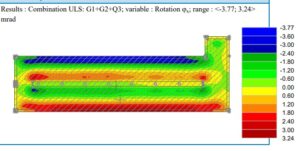

Concrete slab-on-grade locating – a concrete slab poured directly over dirt – involves scanning a trench line for conduits before conducting saw cutting and trenching to install a sanitary pipe, water line, or something similar. [See diagram No. 2]

Rebar Corrosion Scanning ASSESSMENT

Also, crucial in the Concrete rebar corrosion Scanning Daytona imaging process is determining what’s in the concrete structure. This includes gauging the concrete thickness, the rebar content, its spacing, and its elevation within the slab. This extensive, critical information helps our clients and their teams understand the concrete’s makeup. We also can determine concrete covers over the rebar using state-of-the-art equipment.

VOIDS DETECTION AND LOCATIONS

We can also locate voids – air gaps between the sub-grade, dirt, and the concrete slab-on-grade – hidden below concrete or asphalt surfaces. This degradation occurs over time due to compaction, pipe ruptures, or erosion but is often undetectable on the surface. EMA Concrete GPR rebar scan ground penetrating radar can help our clients locate these areas and – most important – avoid collapses.

While MIARA does corrosion of rebars in concrete is done by MIARA, it does not determine what type of object is being located. Project managers are experienced at using all available data in identifying the reinforcing steel or electrical conduit present.

The photo to the left shows a typical post-tension cable mark out. We can locate all of the reinforcing steel anomalies using GPR and other data. We then mark the findings on the concrete and, based on the pattern, can quickly determine what each marking indicates. Most often, when something is on an angle through a square layout, it will be a conduit. You will have a typical rebar pattern with 12-to-18-inch centers. Post-tension cables tend to be spaced further apart, depending on the building’s design and whether they are banded or uniform tendons.